Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Experimental Investigation on Porosity and Permeability Co-efficent for Pervious Concrete Pavement by Statistical Modelling

Authors: SK. Mohisina Tayyiba, Dr. S. Vijaya Bhaskar, N. Rushwanth Chowdary, M. Ruben Pradeep, M. Guru Prasad

DOI Link: https://doi.org/10.22214/ijraset.2024.59467

Certificate: View Certificate

Abstract

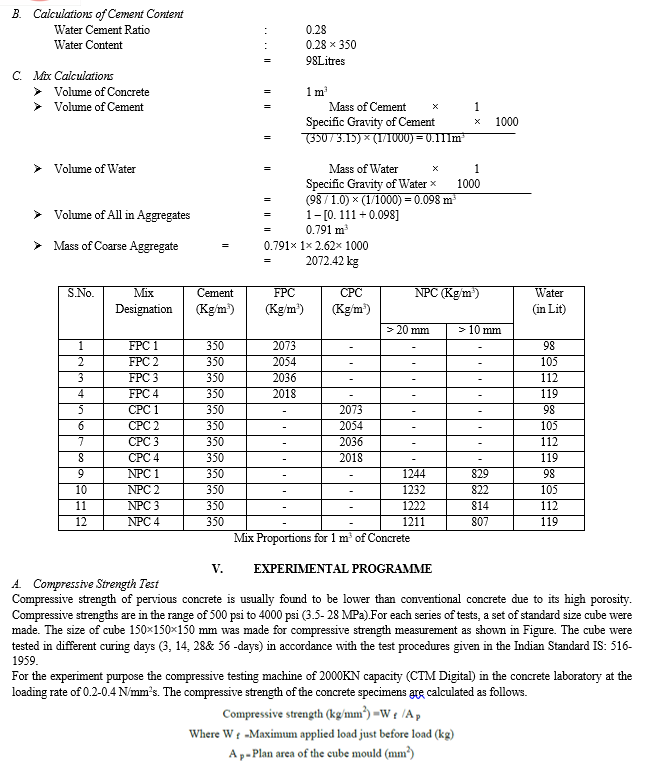

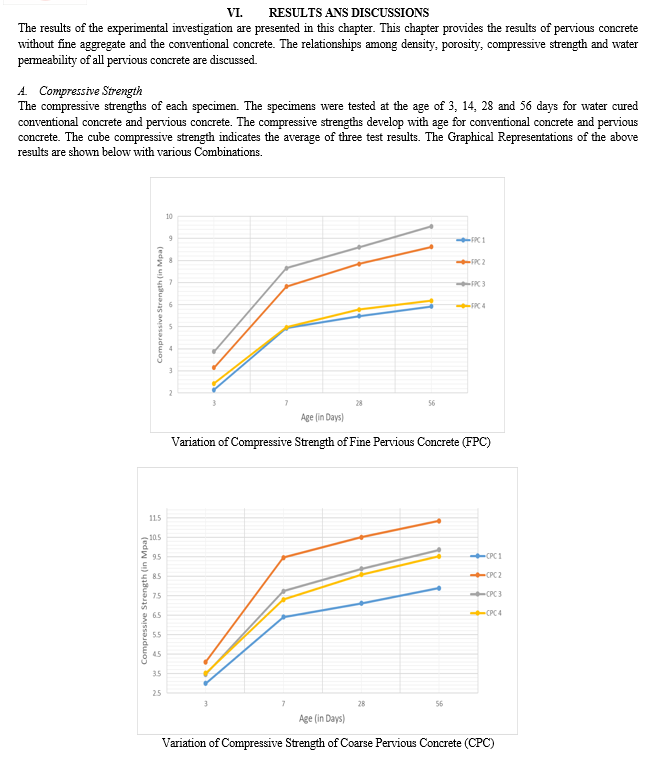

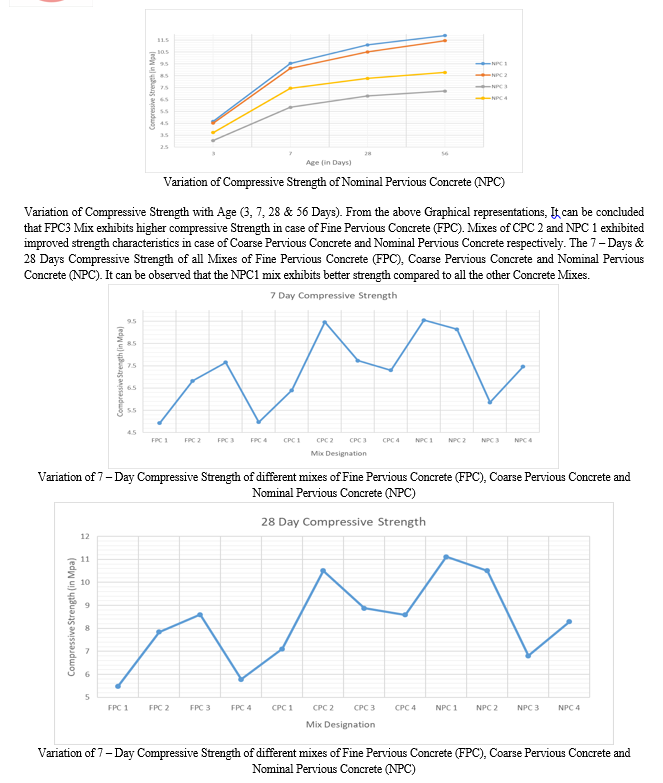

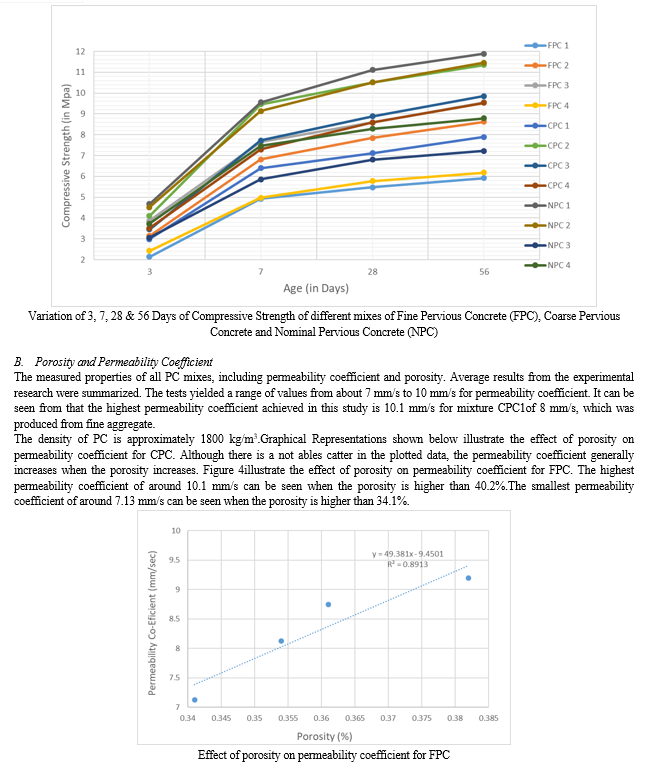

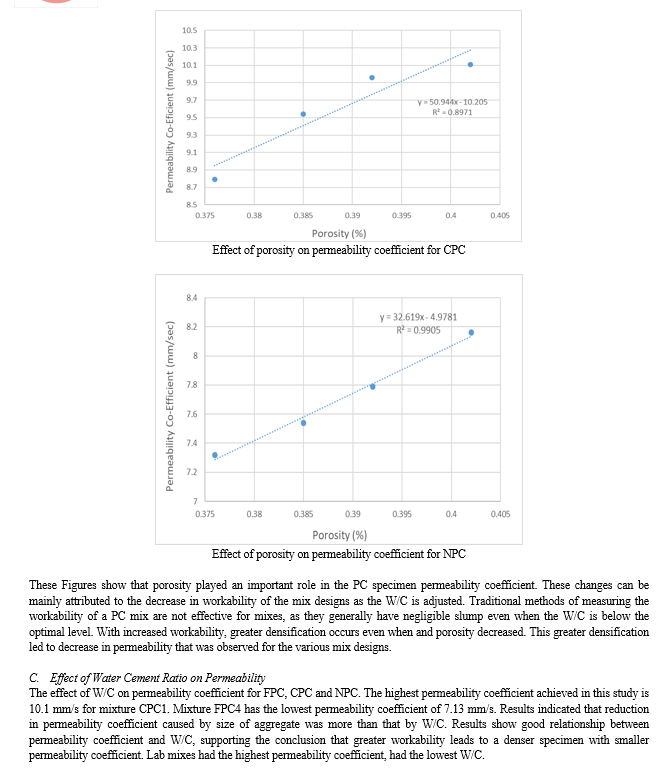

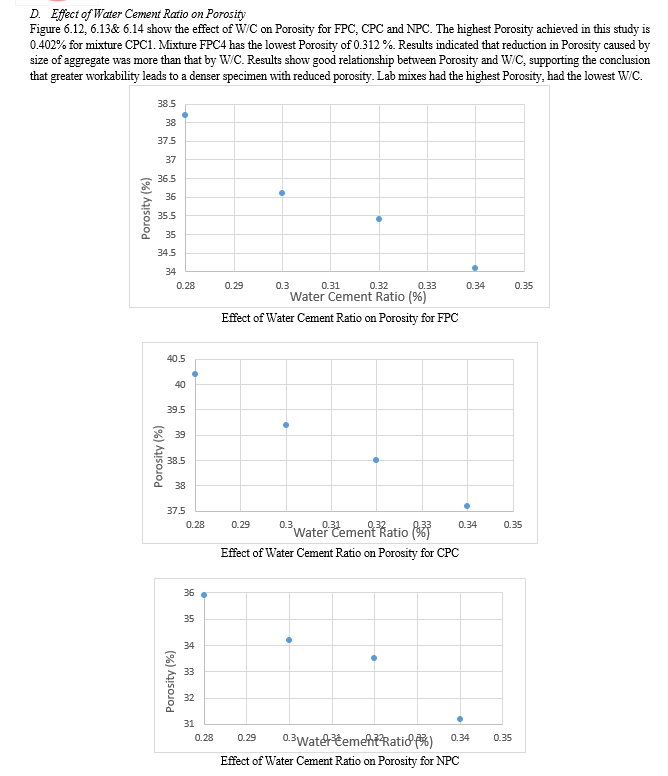

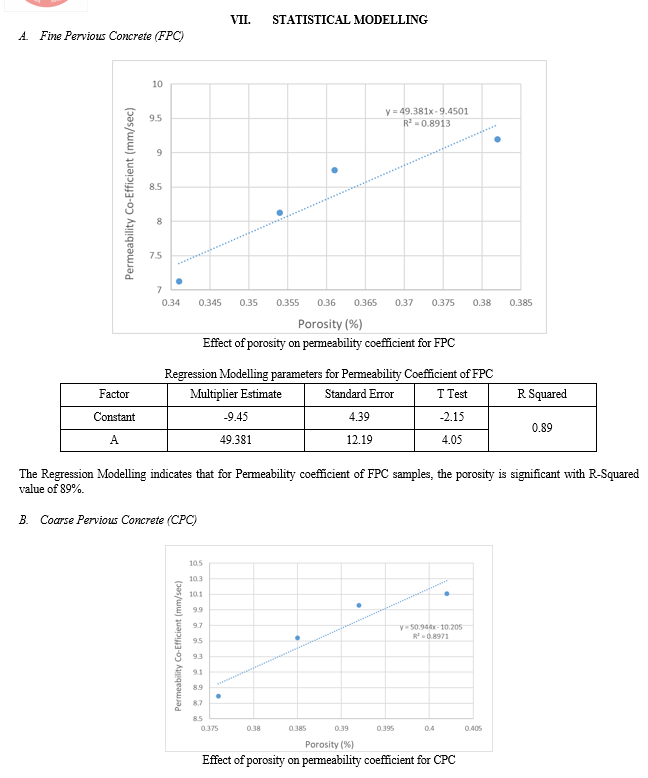

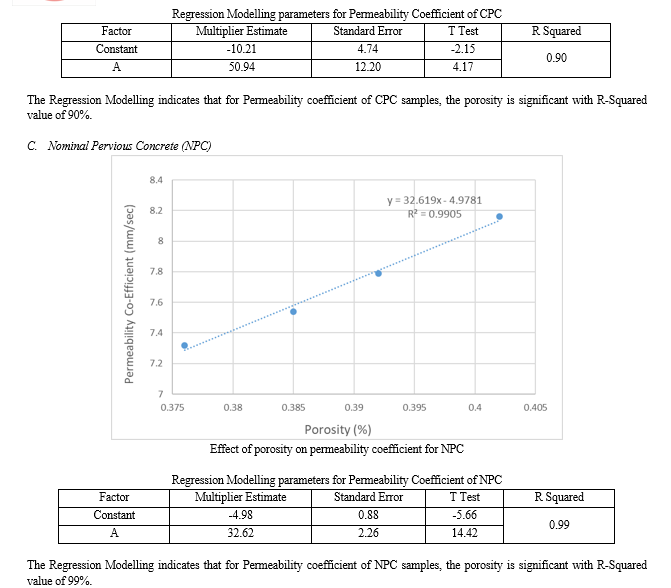

Pervious concrete has varieties of names such as porous concrete, permeable concrete, no fines concrete and porous pavement. It is a special type of concrete with high permeability rate with porosity used for roadways applications that allows water from precipitation and other sources to pass directly through thereby reducing the runoff from a site and allowing recharge. The present research concentrates about bringing out the most efficient porous concrete by varying water cement ratios and size of aggregate. The main properties studied include porosity, compressive strength and water permeability. These properties were compared with those for conventional concrete. Although water permeability is the most important characteristic of the pervious concrete, there is no well-established method for its quantification. Therefore, an experimental procedure to assess the water permeability of pervious concrete is developed. Fine Pervious concrete is considered as FPC, Coarse Pervious concrete is considered as CPC, Nominal Pervious concrete is considered as NPC. Water cement ratios used are 0.28, 0.30, 0.32 and 0.34. It is observed that out of all varying water cement ratios from 0.28 to 0.34, FPC 3 got the highest compressive strength and later it decreased. CPC 2 got the highest compressive strength and later it decreased. NPC 1 got the highest compressive strength and later it decreased. However there is a lot of deviation in compressive strengths from grade of concrete since it is pervious concrete. It looks clear that with increase in water cement ratio there is decrease in Porosity percentage and permeability.

Introduction

I. INTRODUCTION

Conventional normal weight Portland cement concrete is generally used for pavement construction. The impervious nature of the concrete pavements contributes to the increased water runoff into the drainage system, over-burdening the infrastructure and causing excessive flooding in built-up areas. Pervious concrete has become significantly popular during recent decades, because of its potential contribution in solving environmental issues. Pervious concrete is a type of concrete with significantly high-water permeability compared to normal weight concrete. It has been mainly developed for draining water from the ground surface, so that storm water runoff is reduced and the groundwater is recharged. Pervious concrete has been developed in many countries in order to meet Environmental Protection Agency (EPA) storm water regulation requirements. The American Society for Testing and Materials (ASTM) Concrete Committee has focused on this concrete and formed a subcommittee to deal exclusively with pervious concrete production, properties and usage. European countries have developed pervious concrete, not only for water permeability but also for sound absorption. In Japan, pervious concrete has been researched for the usage in not only for road surfaces but also to support vegetation along river banks.Pervious concrete is a relatively new paving material valued for its use as a storm water best management practice. It has environmental benefits such as water pollution removal and maintaining ground water levels. According to Tennis et al. (2004), pervious concrete collects automobile fluids such as oil and anti-freeze and prevents them from being washed into nearby streams or lakes during arain storm. Tennis et al. (2004) also presents the results of two studies that showed very high water pollutant removal rates for pervious concrete. The tests performed showed 82 and 95% total suspended solids removal for pervious concrete, respectively. Pervious concrete also has other benefits. It may increase driver safety by preventing standing water on road surfaces which will decrease hydroplaning and glare (Wanielista & Chopra, 2007).Pervious concrete may also improve land utilization by decreasing the need for detention basins. Some cities are now charging property owners impact fees based on the amount of impervious surface area on their property. Pervious concrete may help property owners avoid theseimpact fees (Tennis et al., 2004). According to Hendrickx (1998) pervious concrete also reduces road noise. This is because the pore structure allows the air between the tire and the pavement to escape, producing a lower frequency road noise. The results of an experiment conducted in Belgium, taken directly from Hendrickx (1998), are depicted in here shows that pervious concrete produced the lowest decibel levels of all the pavements at all four traffic speeds tested.

II. MATERIALS

The materials used in the experimental investigation include:

- Ordinary Portland Cement (OPC)

- Coarse Aggregate

- Water

A. Cement

Ordinary Portland Cement (OPC) of 53 grade of Cement conforming to IS: 12269 standards has been procured and various tests have been carried out according IS: 8112-1989 from them it is found that

- Specific Gravity of Cement is 3.15

- Initial and Final setting times of Cement are 50min and 480 min respectively

- Fineness of cement is 6.0%

B. Coarse Aggregate

Machine Crushed granite aggregate confirming to IS 383-1970 consisting 20 mm maximum size of aggregates has been obtained from the local quarry. It has been tested for Physical and Mechanical Properties such as Specific Gravity, Sieve Analysis, and the results are as follows.

- Specific Gravity coarse aggregate is

- Fineness Modulus of Coarse Aggregate

C. Water

Local Drinking water free flow impurities has been used in this experimental program for mixing and curing.

III. CONCRETE MIX DESIGN

Concrete is a composite material with heterogeneous properties that are vitally dependent on the amount and properties of the constituents. The Concrete mix design is an essential tool in all aspects of concrete technology and its prime objective is to achieve the required compressive strength and workability. Well-developed mix design methods are thus prime tools in securing sustainable industrial concrete construction techniques.

IV. IS METHOD

The IS method recommended the correction factors for different w/c ratios, workability and for shape coarse aggregate. The quantities of fine and coarse aggregate are calculated with help of equations, which are based on specific gravities of the ingredients. Thus plastic density of concrete calculated from yield equation is generally expected to be closer to actual plastic density obtained in laboratory. Thus actual cement consumption will be close to that targeted in the first trial mix itself.

The mix ratio for pervious concrete is maintained as 1:6 and size of aggregate is varied to check the variation in compression, porosity and permeability. As the grade of concrete is M30 it is maintained that 350 kg/m3 was kept constant varying size of aggregate and water cement ratio.

A. Mix Design for M30 Grade of Concrete

|

Grade Designation |

M30 |

|

Type of Cement |

OPC 53 Grade |

|

Maximum Nominal size of Aggregate |

20 mm |

|

Minimum content of Cement |

350 Kg/m3 |

|

Maximum Water Cement ratio |

0.28 |

|

Specific Gravity of Cement |

3.15 |

|

Specific Gravity of Coarse Aggregate |

2.62 |

Mix Design of M30 Grade

Conclusion

Pervious concrete has high water permeability due the presence of interconnected air voids. The presence of high porosity relative to conventional concrete makes the pervious concrete to become light weight concrete with limited compressive strength. However, pervious concrete has been significantly popular for a few decades due to itspotential to reduce the incidence of flooding, and to assist in recharging the groundwater level. This investigation was carried out on the effects of incorporating Fine (<10mm), Coarse (<20mm) & Nominal aggregate (10mm – 20mm), on the properties of pervious concretes. Thepervious concrete properties were compared. A. Compressive Strength 1) Fine Pervious Concrete (FPC):It is observed that out of all varying water cement ratios from 0.28 to 0.34, FPC 3 got the highest compressive strength and later it decreased. Water cement ratio 0.32 got more strength around compared to other water cement ratios. 2) Coarse Pervious Concrete (CPC): It can be clearly stated that out of all varying water cement ratios from 0.28 to 0.34, CPC 2 got the highest compressive strength and later it decreased. Water cement ratio 0.30 got more strength around compared to other water cement ratios. 3) Nominal Pervious Concrete (NPC): It is observed that out of all varying water cement ratios from 0.28 to 0.34, NPC 1 got the highest compressive strength and later it decreased. Water cement ratio 0.28 got more strength around compared to other water cement ratios. How ever there is a lot of deviation in compressive strengths from grade of concrete since it is pervious concrete. B. Permeability Coefficient 1) Fine Pervious Concrete (FPC): It looks clear that with increase in water cement ratio there is decrease in permeability coefficient. FPC 1 is noted to be having greater permeability and there after it reduced with increase in water cement ratios. 2) Coarse Pervious Concrete (CPC): It looks clear that with increase in water cement ratio there is decrease in permeability coefficient. CPC 1 is noted to be having greater permeability and there after it reduced with increase in water cement ratios. 3) Nominal Pervious Concrete (NPC): Similar trend was observed in Nominal pervious concrete, decreasing of permeability coefficient with increase in W/C ratio. But on a overall comparison between FPC, CPC and NPC, it was found that NPC is having lower permeability increasing durability to concrete. C. Porosity 1) Fine Pervious Concrete (FPC): It looks clear that with increase in water cement ratio there is decrease in Porosity percentage. FPC 4 is noted to be having least porosity. 2) Coarse Pervious Concrete (CPC): It looks clear that with increase in water cement ratio there is decrease in Porosity percentage. CPC 4 got least porosity values compared to other coarse pervious concrete proportions. 3) Nominal Pervious Concrete (NPC): Similar trend was observed in Nominal pervious concrete, decreasing of Porosity percentage with increase in W/C ratio. But on a overall comparison between FPC, CPC and NPC, it was found that NPC is having lower Porosity percentage increasing strength of concrete by reducing voids.

References

[1] Ajamu S.O., Jimoh A.A. and Oluremi J.R, Evaluation of Structural Performance of PerviousConcrete in Construction, International Journal of Engineering and Technology,2 (2012):pp.829-836. [2] AlaicaA.L. ,Dolatabadi M.H. Sucic A. and Shehata M.,Optimizing the strength and permeability of pervious concrete, Paper prepared for presentation at the permeable pavement design and technology session of the annual conference of the transportation association of Canada Halifax, Nova Scotia,(2010):pp.1-19. [3] Aoki, Y. and Sriravindrarajah, R., Shrinkage of environ-mentally friendly sustainable porousconcrete, Proceedings of the international conference on sustainable concrete construction.Ratnagiri, India, (2007):pp.1-4 [4] Aoki Y., Sriravindrarajah R. and Khabbaz H., Environmentally friendly sustainable pervious concrete, Proceedings of the 20th Australasian conference on the mechanics of structures andmaterials, Toowoomba, Australia, (2008) . [5] Aoki, Y., Sriravindrarajah, R. and Khabbaz, H.,Effect of fly ash performance of pervious concrete, In Supplementary proceeding of tenth CANMET/ACI international conference onrecent advances in concrete technology and sustainability issue. Seville, Spain, (2009):pp.1-8. [6] Aoki Y., Ravindrarajah R. and KhabbazH.,Properties of pervious concrete containing flyash Road Materials and Pavement Design,13(2012): pp.1–11 [7] Aoki, Y., Sriravindrarajah, R., &Khabbaz, H.,Properties of pervious concrete containing flyash, Road Material sand Pavement Design,(2012 ): pp.1–11. [8] Bradley J. Putman. and Andrew I. Neptune, Comparison of test specimen preparationtechniques for pervious concrete pavements, Construction and BuildingMaterials,25(2011):pp. 3480–3485 [9] Baoshan H., Hao Wu. Xiang Shu. and Burdette.E.G., Laboratory evaluation of permeabilityand strength of polymer-modified pervious concrete ,Construction and Building Materials, 24(2010):pp. 818–823 [10] Carsana M., Tittarelli F. and BertoliniL ,Use of no-fines concrete as a building material:Strength, durability properties and corrosion protection of embedded steel ,Cement andConcrete Research, 48 (2013): pp.64–73. [11] Delatte N. and Schwartz S.S.,Sustainability, Benefits of Pervious pavement, SecondInternational conference on sustainable construction materials and technologies,(2010):1-9 [12] Geso?lu M., Güneyisi E. Khoshnaw G. and ?pek S, Investigating properties of perviousconcretes containing waste tire rubbers, Construction and Building Materials,30(2014):pp.206–213. [13] Hossain T., Salam M. and Abdul M.K., Pervious concrete using brick chips as coarseaggregate: An experimental study, Journal of Civil Engineering (IEB), 40(2012):pp.125-137. [14] Ibrahim H.A., and Razak H.A., Effect of palm oil clinker incorporation on properties on pervious concrete, Construction and building material , 15(2016): pp.70–77 [15] Jang J.G., Ahn Y.B., Souri H., Lee H.K, A novel eco-friendly porous concrete fabricated withcoal ash and geo polymeric binder :Heavy metal leaching characteristics and compressivestrength ,Construction and Building Material, 29(2015):pp. 73-78

Copyright

Copyright © 2024 SK. Mohisina Tayyiba, Dr. S. Vijaya Bhaskar, N. Rushwanth Chowdary, M. Ruben Pradeep, M. Guru Prasad. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59467

Publish Date : 2024-03-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online